Thermographic measurements* focusing on:

- diagnosis of machinery in terms of bearing condition, lubrication, etc.

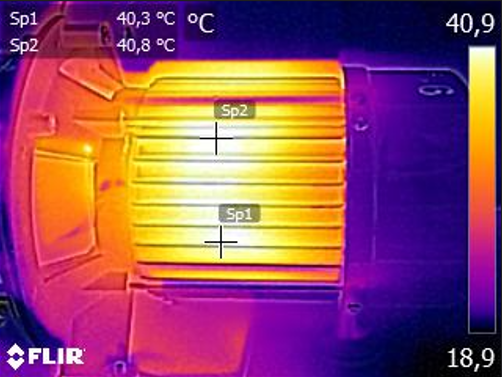

- informative inspection of the technical condition of electric motors (possible detection of imperfect electrical connections, short circuits, damage, etc.), photovoltaic panels (if there is suitable access to them – identification of overheated places), etc.

- thermal diagnostics of objects (Searching for thermal bridges – places of heat leaks, e.g. also as a result of incorrectly installed or leaky windows and doors – these leaks, among other things, also increase the costs of heating, checking the quality of insulation, identifying places of potential mold growth, etc. The output is a protocol from the thermographic measurement with a description of the identified deficiencies, possible causes, as well as relevant visual documentation – thermal images, photographs, etc.)

- identification of the condition of heat exchangers (clogged radiators), pipes of heating systems (detection of a leak without the need to open the entire floor or wall, finding the position of built-in pipes, etc.)

- detailed analysis of temperature fields – e.g. to obtain temperature profiles in certain places, analysis of temperature development over time in a certain place (radiometric video recording) and so on.

* Measurements and analyses are performed using a calibrated FLIR E8XT thermal camera and FLIR Thermal Studio software.